Before our deep-dive into commercial applications for thermal sensor security cameras we thought it would be helpful to take a look at how the technology actually works in these higher end cameras and how thermal cameras differ from traditional HD video security cameras.

Vulcan Security Systems, serving businesses across north central Alabama, is a big fan of Mobotix camera line, so we will use their product guides to explain how the sensor-equipped thermal cameras work.

Update September 10, 2018: Mobotix S16B Thermal TR (thermal radiometry) security camera was recently named as Security Today’s outstanding Video Surveillance Cameras – Thermal (category) in the Security Today’s 2018 New Product of the Year awards. We discuss some of the features of this camera later in this article.

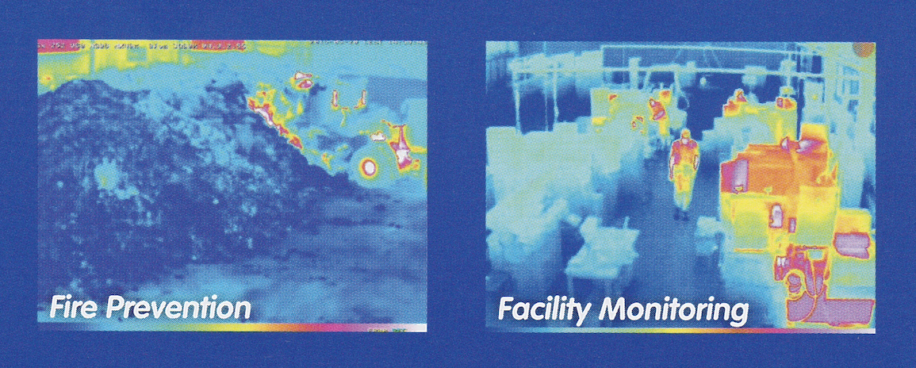

Thermal cameras identify the presence of people or objects by “reading” electromagnetic radiation emitted from the person or object based on temperature. The variation in temperature of people, animals and/or objects in the field of view is mapped using color patterns based on heat intensity.

Mobotix thermal cameras can be equipped with a optical lens, allowing the user to overlay the thermal image onto the visual image so that the exact location of the heat source can be quickly identified. This dual capacity allows one Mobotix camera to perform both thermal radiography and normal video monitoring.

Thermal cameras are a great option for low-light or no-light areas that require security cameras. The Mobotix line can detect objects and people via thermal radiation at distances of up to 400 meters.

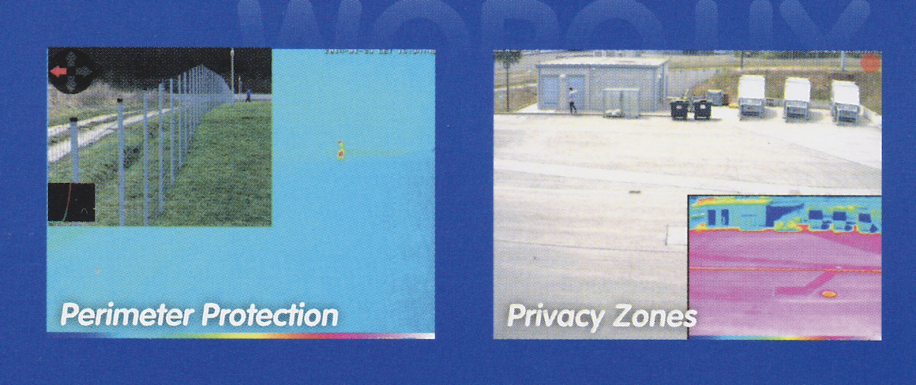

Mobotix dual thermal cameras are especially useful in monitoring large outdoor areas, such as in perimeter security applications, through the combination of thermal radiography, HD video sensors and Mobotix MxActivitySensor intelligent software. This triple-play eliminates the need to use IR-conventional light technology or other types of sensors.

The degree to which the camera can adequately map temperature variation depends on the quality of the sensor onboard the camera.

Thermal Sensor Sensitivity

The quality or grade of sensor determines the range of temperature variation that can be detected by a thermal camera. The variability is known as the Noise Equivalent Temperature Difference (NETD) and is measured in milikelvin (mK).

In practical terms, the NETD “score” is the thermal resolution of the camera, allowing users to compare thermal cameras across product lines, brands, and also to select thermographic cameras that best fit the objectives for deployment.

Mobotix cameras use a sensor with NETD of 50. These cameras are capable of identifying temperature variation “starting at ones of 0.05 degree C (0.09 degree F), in the range of -40 to +550 degree C (-40 F to 1022 F).” [Mobotix website.]

The Mobotix camera line can also be upgraded to include a sensor that is calibrated to detect minute changes in temperature in a defined surface area and trigger programmed events based on increases or decreases in temperature. This allows the camera to be used as a monitoring device to automatically initiate preventive actions, such as shutting down a manufacturing line if a machine suddenly appears to be overheating.

Thermal Security Cameras and Privacy

As mentioned above, the Mobotix line of thermal cameras can be equipped with an optical sensor to capture and deliver high resolution video when needed.

This dual functionality makes it possible to use the thermal radiography for security in sensitive areas–like swimming pools, sports facilities and hospitality settings–without capturing detailed facial or other physical attributes that would allow for identification. These cameras can be programmed to automatically switch on the optical sensor to capture high definition visual video if movement is detected in the defined zone of interest.

Thermal Radiation and Glass Barriers

Thermal cameras cannot easily or accurately detect temperature variation in areas where glass separates the camera from potential heat sources. However, with Mobotix cameras, additional camera modules can be added to the thermal unit for visual monitoring capabilities.

Over the next few weeks we’ll be sharing some case studies and specific uses for thermal security cameras across various commercial and industrial settings.

If you have a specific application question that you would like to see addressed in this series, feel free to contact Vulcan Security Systems and let us know.