Machine uptime and efficient quality control are two of the keys to profitability in manufacturing.

In this article, we will take a look at how video cameras equipped with thermal sensors can help plant managers, maintenance engineers and quality control engineers prevent problems and hit their production goals.

Thermal cameras, also known as infrared cameras, are increasingly being put to use in industrial settings across many sectors of today’s economy. From data centers to materials handling facilities to veterinary practices to food processing to biotech to traditional manufacturing and mining facilities–each context is seeing intense growth in deployment of cameras capable of reading “thermal fingerprints.”

Two quick examples for non-obvious applications of thermal cameras in manufacturing:

- Quality control monitoring in the production of glass bottles that must be heated to a specific temperature during the manufacturing process.

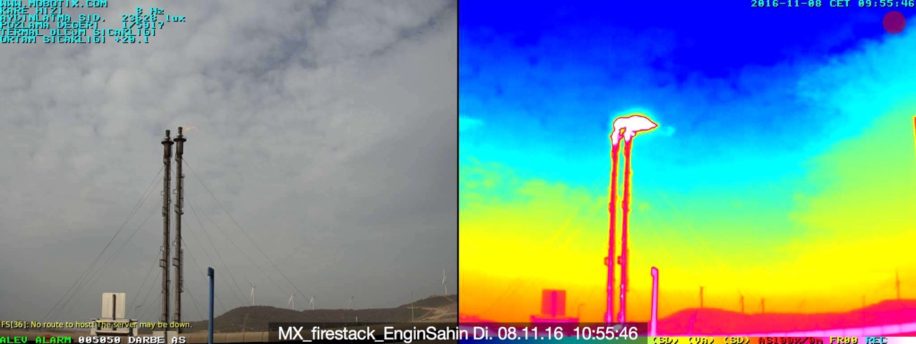

- Flare stack monitoring for pollution control compliance

This is article is one of a series we’ve been publishing here at Vulcan Security Systems, to help explain how thermal video cameras work and how they can be used in industrial and other commercial environments.

The sensors in thermal cameras, like the Mobotix M16 and S16 Thermal Series, are capable of detecting temperature variation at levels as small as 0.09°F (0.05°C) across the range of -40°F to 1022°F (-40°C to 550°C).

Source: https://www.mobotix.com/en/products/thermographic-cameras

This high level of thermal sensitivity, coupled with sophisticated visualization software, means the cameras can be used to monitor a production for operational purposes, as well as equipment monitoring for preventive maintenance.

The thermal cameras can be programmed to notify the supervisor, maintenance engineer or safety personnel if a sensor detects a reading above or below the desired parameters or even shut down a production line or machine to prevent or minimize loss or damage to equipment and materials. This automation feature eliminates damage that might occur due to a delay in human response time.

Mobotix and other high-end thermal cameras can be integrated with SCADA and many other manufacturing control systems and software applications.

“Mobotix thermal cameras can monitor up to 20 points in the field of view,” says Mark Heintzman, business development manager for Mobotix.

The thermal cameras also support remote monitoring by safety, production, and maintenance personnel, just as with traditional IP video security cameras.

The remote-monitoring capabilities are vital in applications like flare stack monitoring for EPA compliance, mentioned earlier. Optical camera monitoring of the flare stack isn’t ideal, because occasionally the flame burns clear. The IR camera can always read the thermal fingerprint and determine if the flare stack flame and/or pilot light flame is burning.

If you have questions about thermal imaging cameras and how they might be used in your company’s industrial operation, give us a call. We have see increasing interest in thermal cameras among our current client base and are handling an upgrade and expansion of video security system installations right now for two of our industrial clients, both who wanted thermal cameras added as part of the expansion.